Testing & Validation Services

Tap on the microscope pictures to discover different applications...

Swipe right for an introduction...

Advanced Friction Testing

Incorporating temperature, roughness and stiffness characteristics

Tap the design to learn more...

Optimization of Polymer Designs

Actual strength and stiffness for the shape envisioned

Tap the design to learn more...

Incorporation of New Products

Test before application to assure functionality

Tap the design to learn more...

Coating Deterioration Testing

Avoiding surprises in hindsight by simulating operations beforehand

Tap the design to learn more...

Improve Bearing Selection

Validate friction of sliding bearings and reduce actuation power and consequential costs

Tap the design to learn more...

Validate Securing Systems

Determine locking and holding capability of interfacing elements

Tap the design to learn more...

Mitigating Mudmat Suction

Reduce risks and costs with innovative foundation solutions

Tap the design to learn more...

Improve Designs with Wood

Avoid using rare & expensive wood species by suitability testing

Tap the design to learn more...

Test Maintenance Impact

Assure reliability of components by estimating wear and improving maintenance

Tap the design to learn more...

Monitor Accelerations

Monitor fatigue economically during long transports or validate your motion analysis

Tap the design to learn more...

Goal Testing & Validation Services

Perform pragmatic tests with a short lead time to:

1. Create better designs & calculations

2. Improve safety & workability

3. Optimize procurement (cost) of non-steel materials

4. Detect & prevent damage

Click here return to the homepage

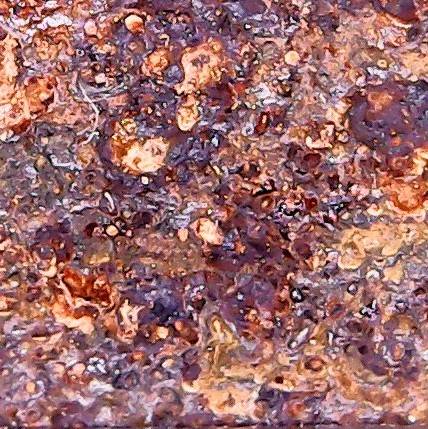

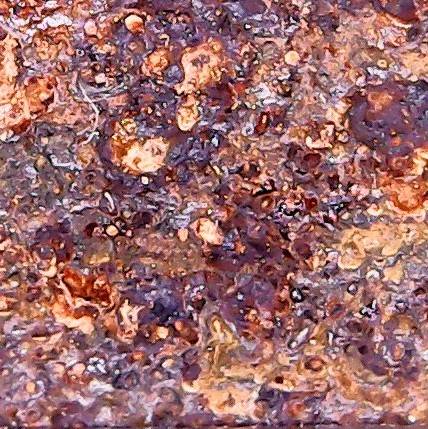

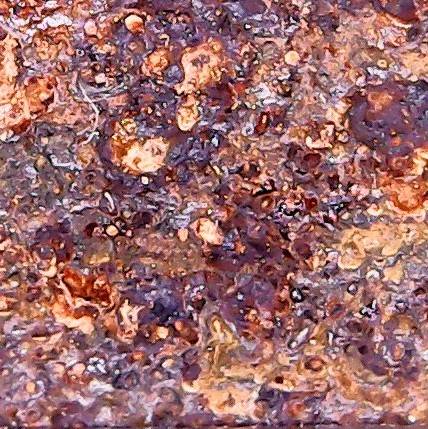

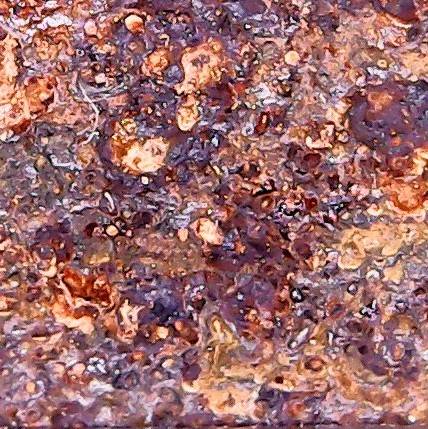

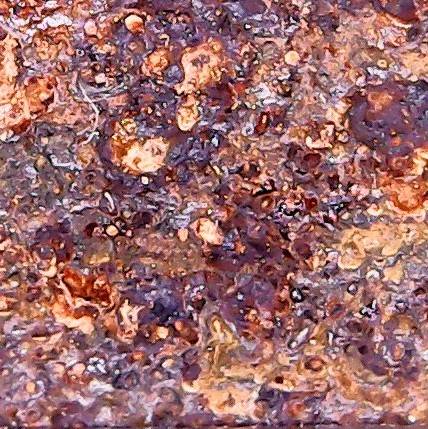

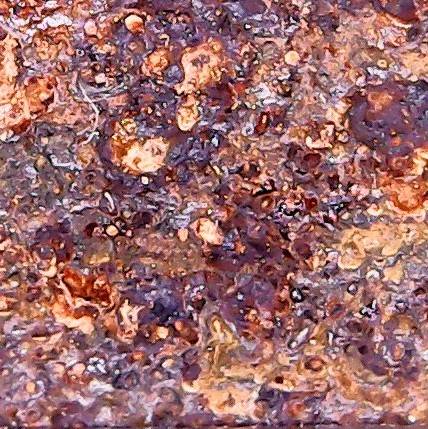

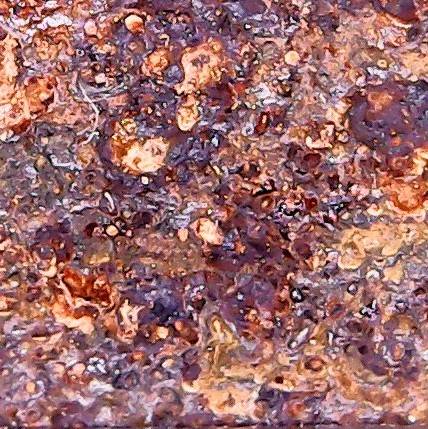

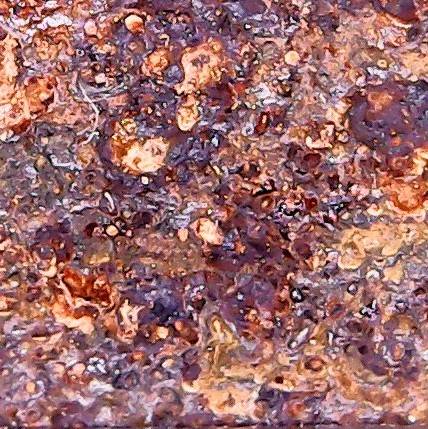

Advanced Friction Testing

Design frictional interfaces in line with:

1. Roughness of counter-face

2. Corrosion as well as wear & tear

3. Design temperatures, up to arctic conditions

Test with short lead time for recurring applications

Click here return to the homepage

Validation Against Full Scale Measurements

To check whether small scale results are representative for full scale situation.

Click here return to the homepage

Identical material & conditions. 8 different counter-surfaces. 8 different friction values.

Click here return to the homepage

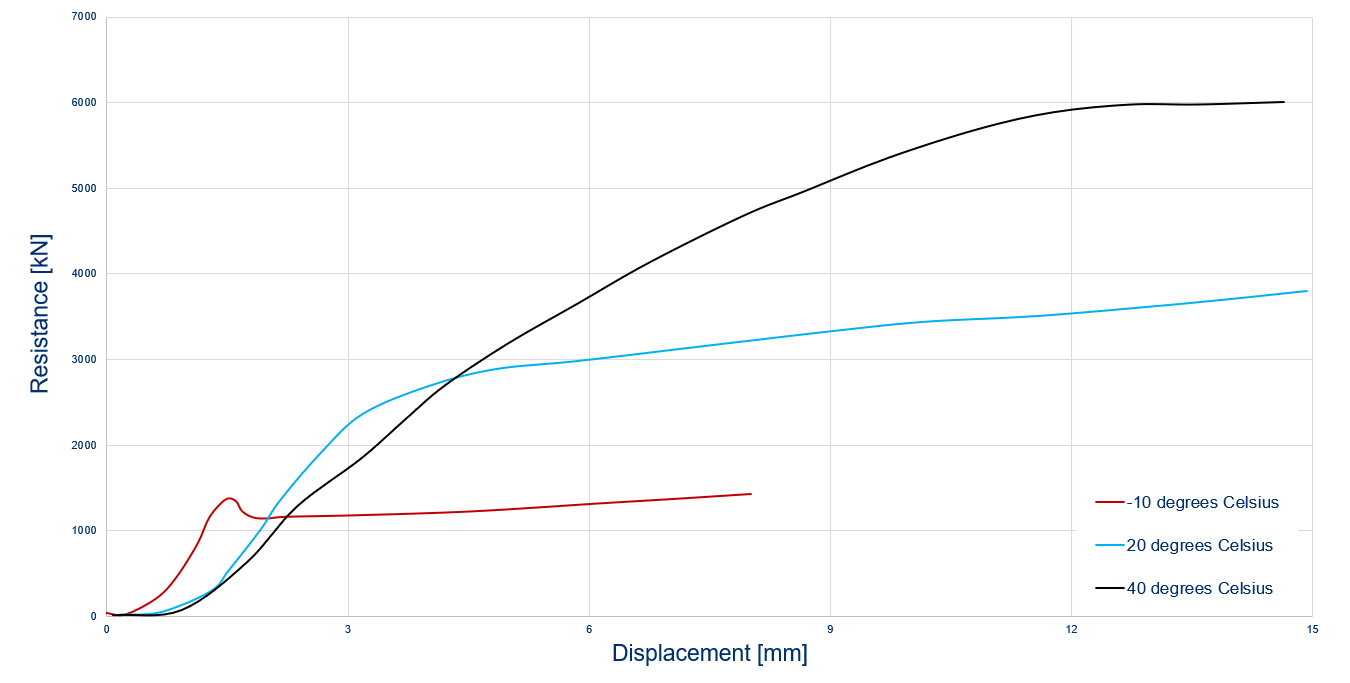

At low temperatures friction can change significantly depending on the polymer material composition.

Click here return to the homepage

Stiffness can vary by factor 10 for your range of design temperatures.

Click here return to the homepage

Avoiding assuming friction values in your project but validate them. For example of slings against clamps:

Click here return to the homepage

Test within days according to DNV validated procedure for many available material combinations.

Click here return to the homepage

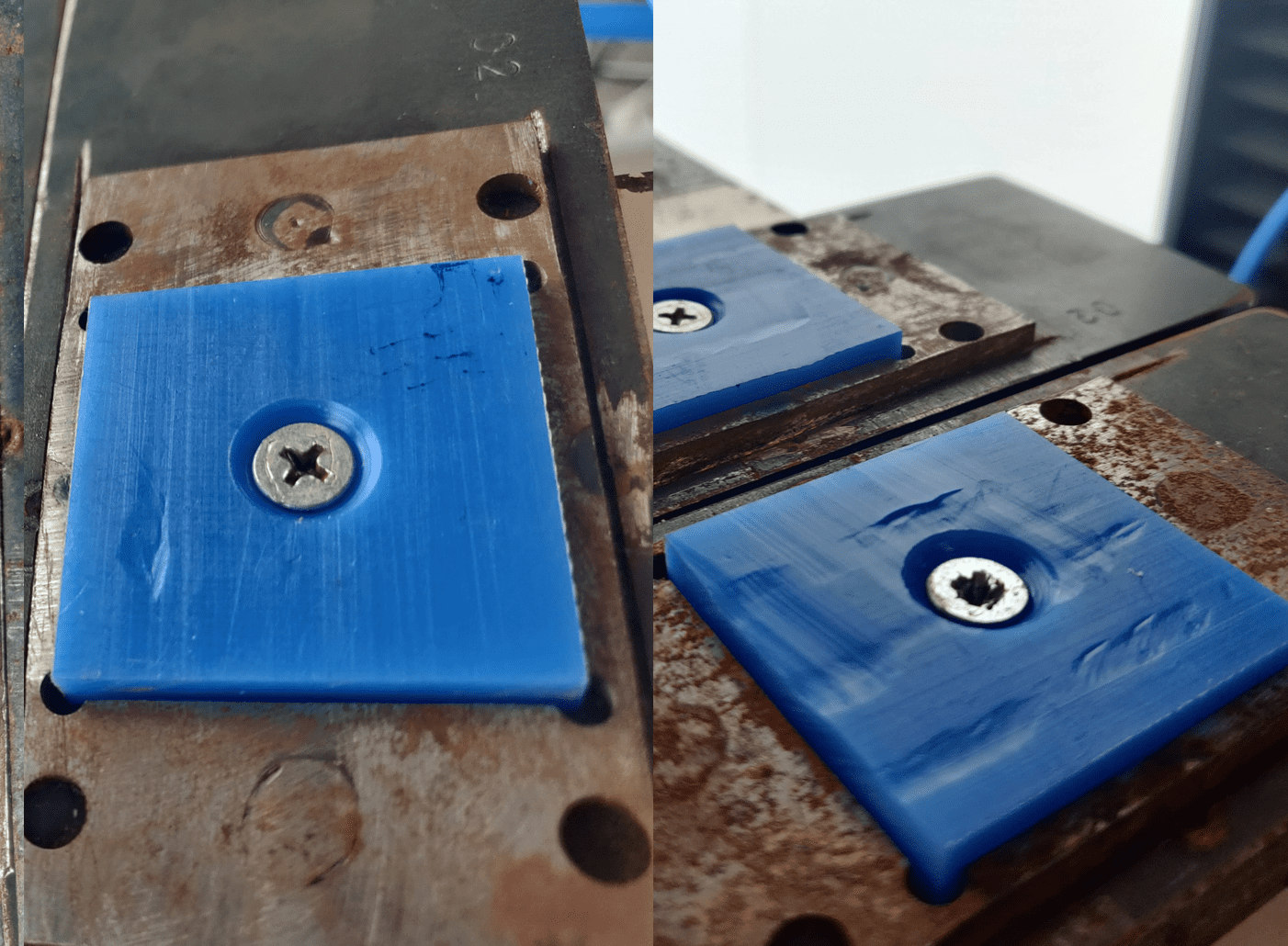

Use actual strength & stiffness to:

1. Avoid incorrect design input

2. Improve structural integrity of handled objects

3. Increase cost-efficiency in procurement

Test developed in collaboration with DNV

Click here return to the homepage

Polymers are never isotropic. Sometimes even incompressible. This can have large implications.

Click here return to the homepage

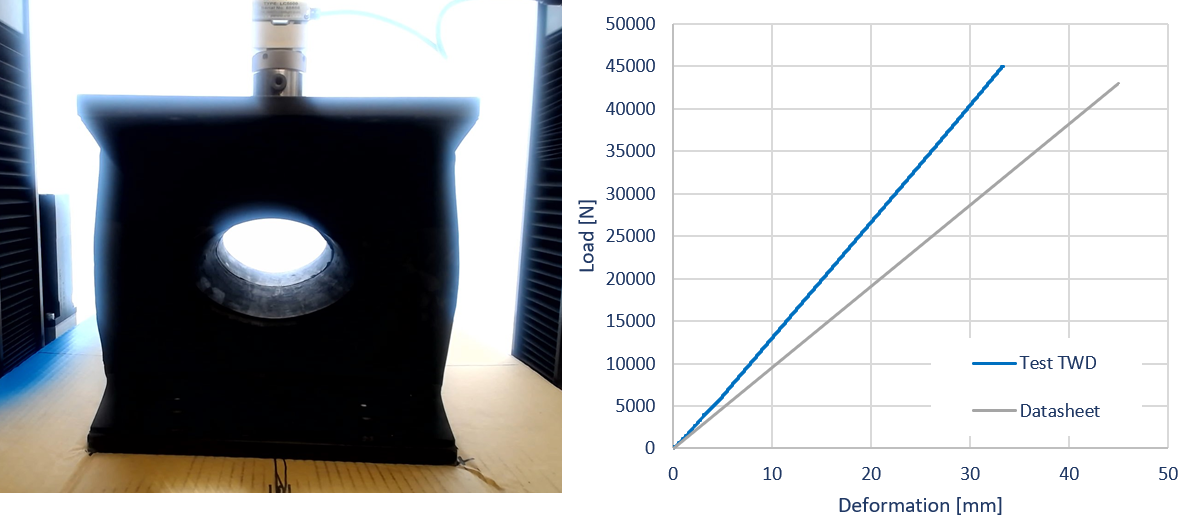

Shape matters. Validate strength & stiffness according to procedure developed together by TWD & DNV.

Click here return to the homepage

Dampers and seals need to be one-time-right. Catalog and small scale tests are often inaccurate.

Click here return to the homepage

Achieve stress reductions up to 20% at interface by properly accounting for behavior of polymer supports.

Click here return to the homepage

Proof of concept for innovations like:

1. 3D printed filler blocks

2. Custom Anti-Slip coating

3. Landfastening on EPS

4. Geotextile application in offshore environments

5. Alternative sling handling interfaces

Click here return to the homepage

Use a TWD developed coating which optimizes safety for your operations

Click here return to the homepage

Replace expensive steel elements with recyclable filler elements and load test them.

Click here return to the homepage

Replace temporary steel supports of equipment by cheap and light EPS.

Click here return to the homepage

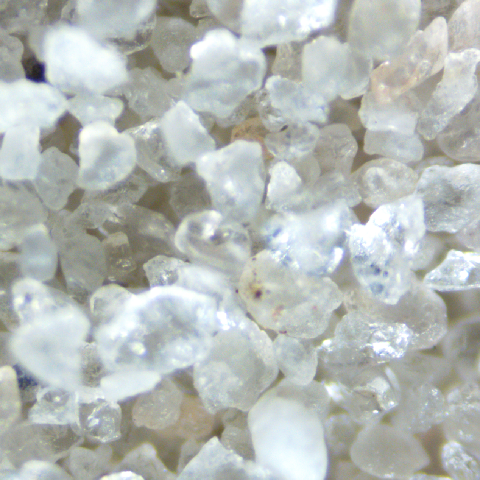

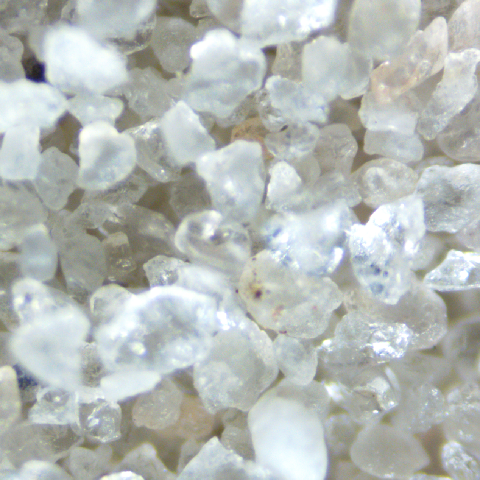

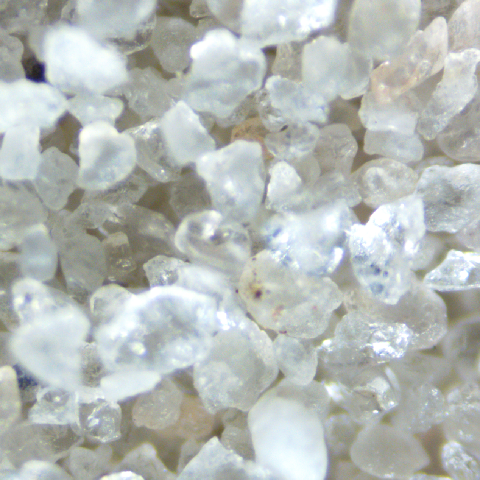

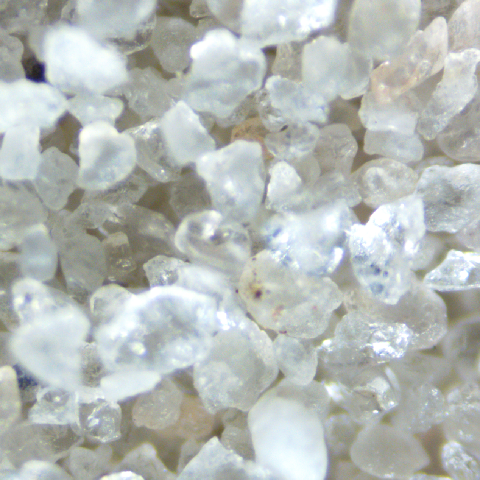

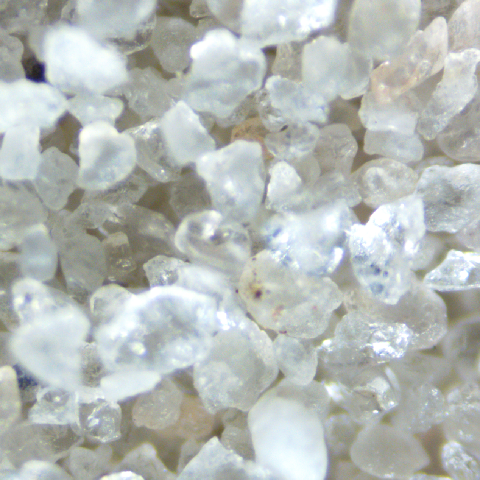

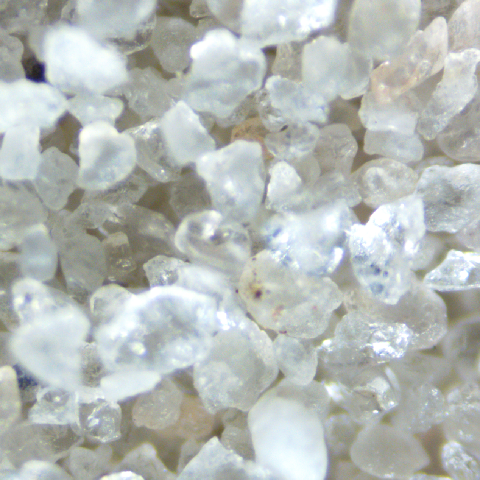

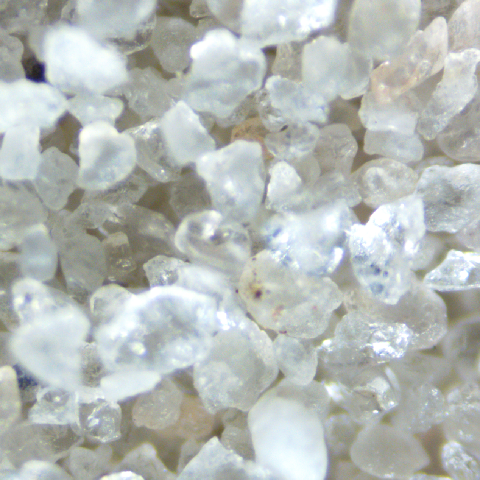

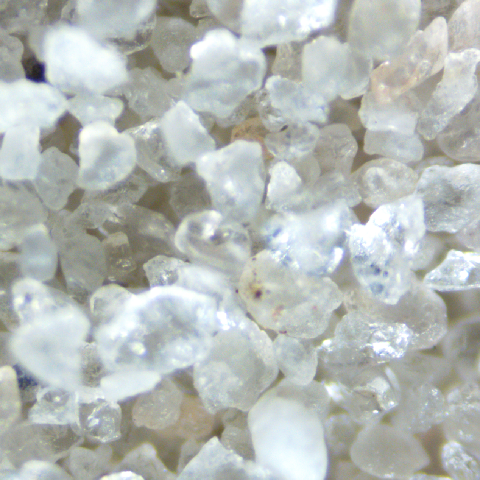

Avoid inflow of sand on spudcans and mud-mats using geotextile (or mitigate other risks).

Click here return to the homepage

Avoid damage to soft slings and optimize interface design by prototyping and testing.

Click here return to the homepage

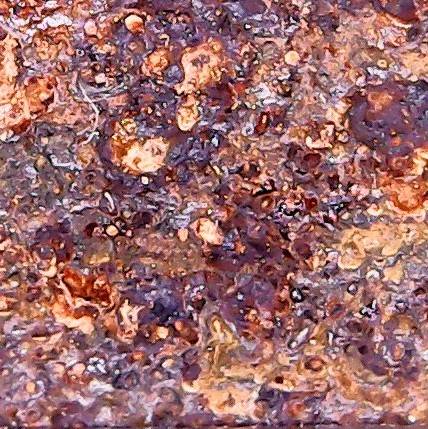

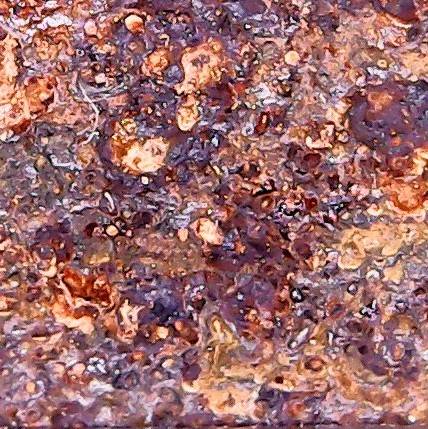

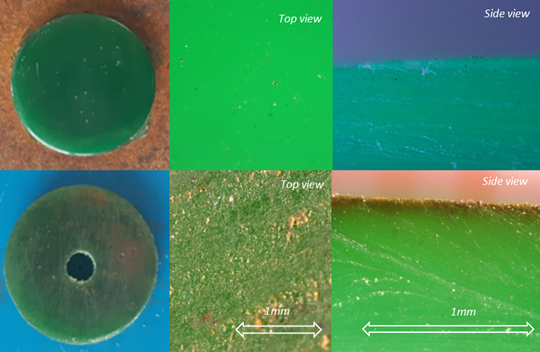

Coating becomes an attention point in projects due to:

1. Exotic coatings (thicker and alternative materials)

2. Higher surface pressures due to scale-up wind sector

3. Longer transports and installation operations

Simulate & crash-test according to ISO-4628

Click here return to the homepage

Use TWDs extensive experience with handling a wide variety of coatings.

Click here return to the homepage

Transit and installation conditions and corresponding contact pressures and shear loads significantly increased.

Click here return to the homepage

Simulate design conditions and validate damage according to ISO-4628. Optimize designs based on results.

Click here return to the homepage

Difference in lifetime between loaded and not loaded interfaces to be avoided.

Click here return to the homepage

Bearings challenging when designing actuated systems:

1. Conservatism cause overdesigned actuation (€)

2. Unconservative assumptions lead to blockage (€)

3. Avoid maintenance or grease by optimizations

4. Become independent and make right decisions

Results in optimized costs for actuation & bearings

Click here return to the homepage

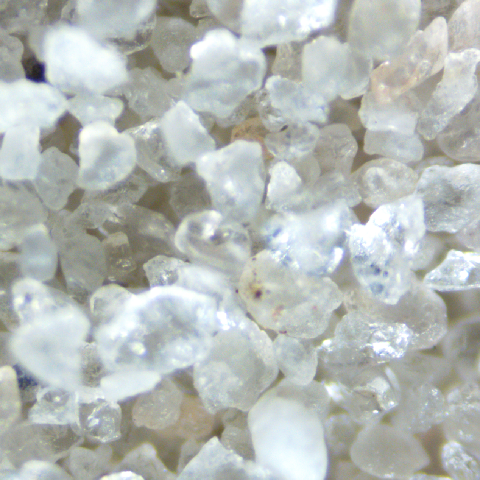

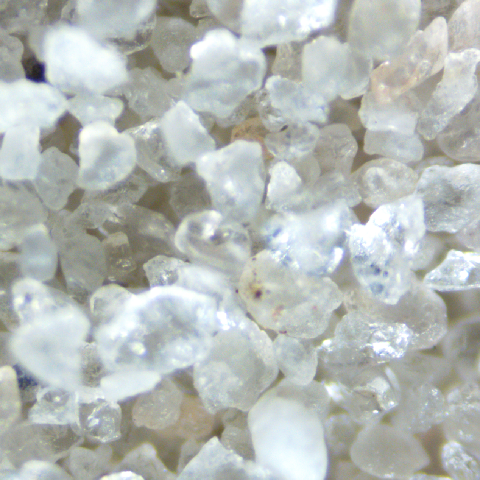

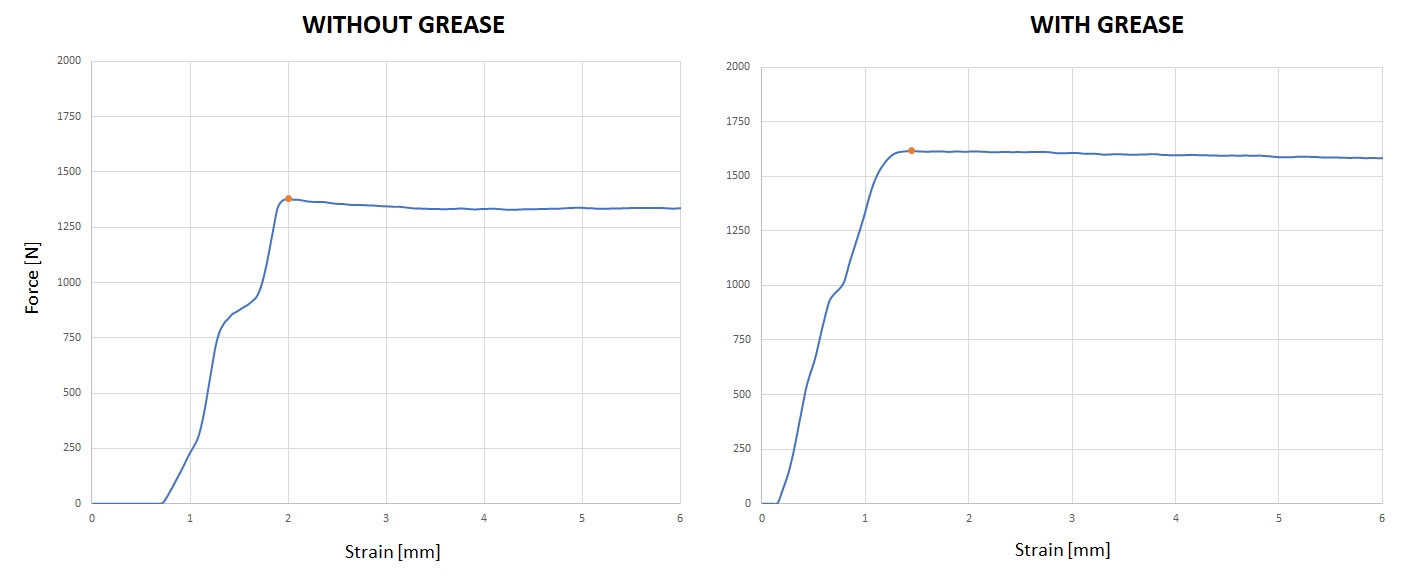

Common myths and talks concerning skidding:

1. Low vs high roughness skid-tracks

2. Heat generation of material combination

3. To grease or not to grease?

4. Stick-slip prevention for large skid-tracks?

Skidtracks are a system design and should be tested!

Click here return to the homepage

Especially in linear systems grease can collect dirt or cause stick-slip.

Click here return to the homepage

Only procuring bearings is insufficient, system understanding is required

Click here return to the homepage

Common rules of thumb might not always be applicable:

1. Corrosion counterface changes behavior

2. Minimum contact loads required change per material

3. Re-usability of systems over different projects

Assure functionality of these most important interfaces

Click here return to the homepage

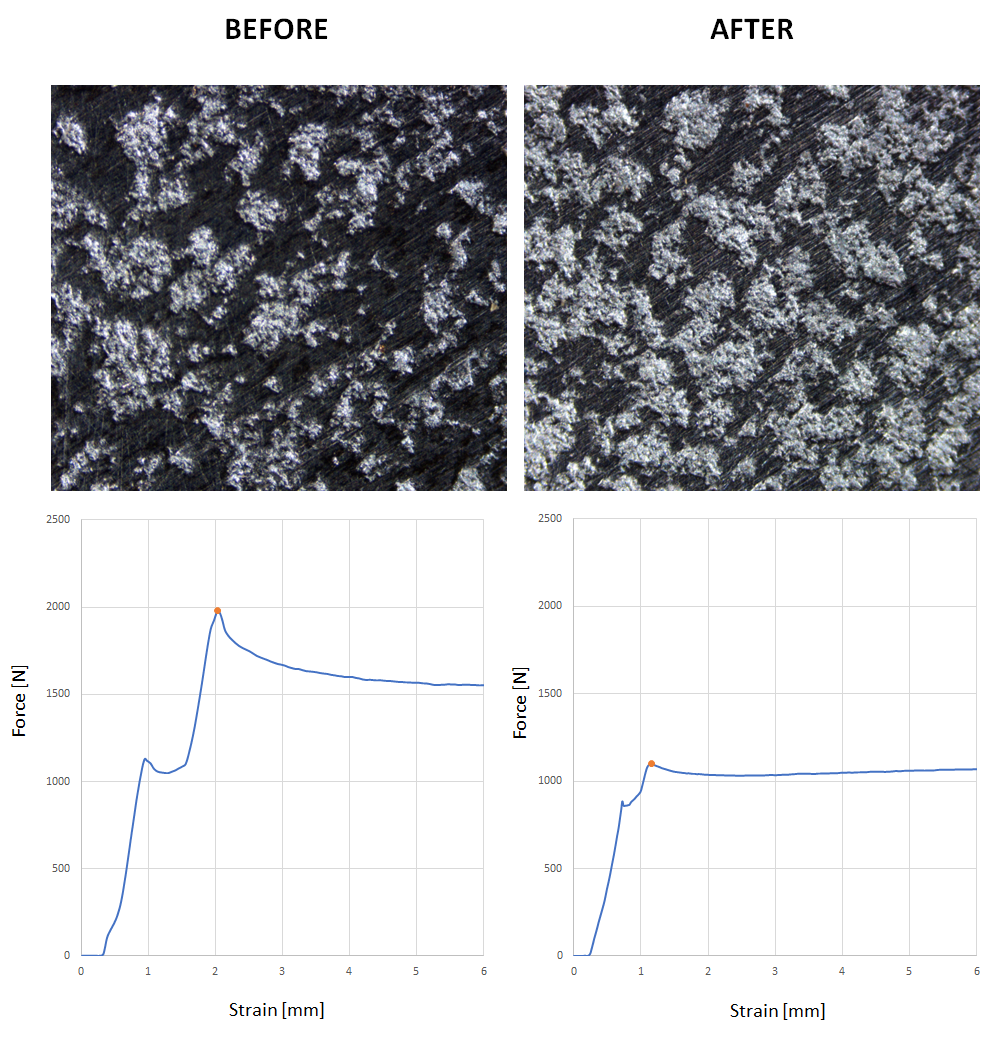

Due to a smaller true area of contact the resistance reduces significantly.

Click here return to the homepage

Determine optimal clamp design by testing to maximize resistance and avoid sudden failure.

Click here return to the homepage

Check on permanent damage due to operational and accidental loads from clamp.

Click here return to the homepage

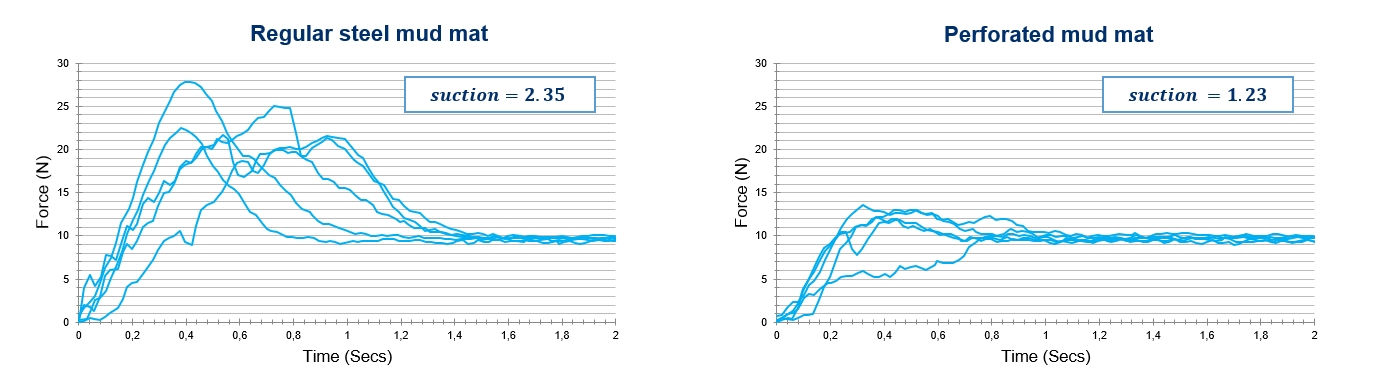

Improve mud-mats by applying permeable interfaces to:

1. Reduce suction loads and overall template weight

2. Improve horizontal stability on the seabed

3. Avoid costly jetting systems with limited functionality

Currently tested for different soil & loading conditions

Click here return to the homepage

Design codes require 2.5 lifting factor due to suction developing at the mud-mat soil interface.

Click here return to the homepage

Accurately measuring type and amount of suction relief on small scale.

Click here return to the homepage

Applying innovative mitigations (holes, textiles & layering) reduces suction up to 200%.

Click here return to the homepage

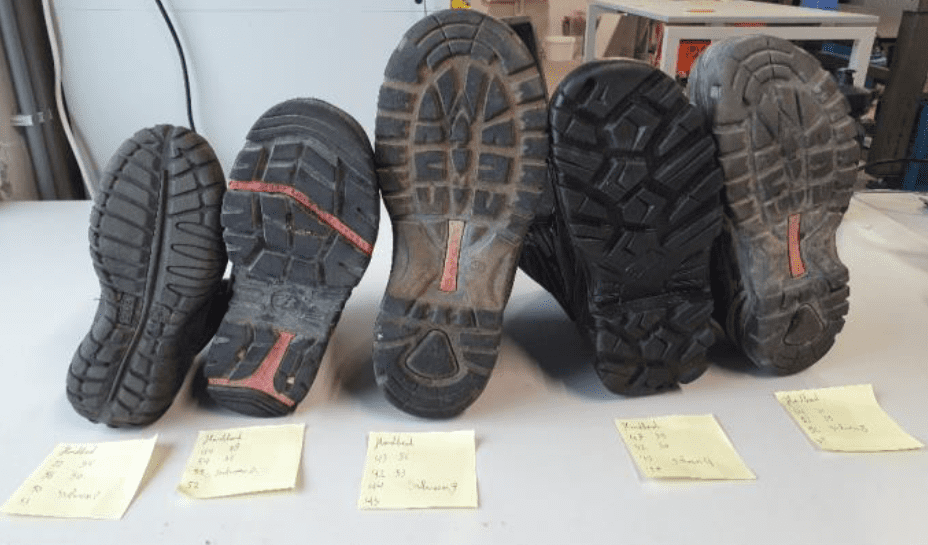

Wood is still suitable to use in T&I equipment:

1. High friction at low contact pressures

2. More cost efficient and sustainable than steel

3. Easier workable and to be customized

Testing soft-wood as alternative for exotic types

Click here return to the homepage

Softwood performs better than hardwood in some contact pressure ranges.

Using thin sheets of softwood instead of hardwood can cause large cost benefits.

Click here return to the homepage

Softwood performs better than hardwood in some contact pressure ranges.

Using thin sheets of softwood instead of hardwood can cause large cost benefits.

Click here return to the homepage

Using wood for seafastening is more cost efficient, reduces stresses at interface and increases flexibility.

Click here return to the homepage

Simulate to check wear of shims and sliding interfaces:

1. Improves estimates of tolerances in structural design

2. Selecting the ideal material for the structure to be used

3. Longer re-use due to proven maintenance schedules

Essential for optimal use of any non-standard component

Click here return to the homepage

Determine correct shim material which avoids coating damage and is highly wear resistant.

Click here return to the homepage

Corrosion impacts friction pads with more than 30%. This is unsafe and replacement is costly.

TWD verified cleaning and maintenance procedures restoring the original frictional capacity.

Click here return to the homepage

Swapping a € 15.000,- measurement device for a € 3.000,- for long distance transports

Click here return to the homepage

Reduce cost and risk of future similar operations